Table of Contents

Protecting intellectual property (IP) from theft and safeguarding data takes more than cybersecurity on your systems. Companies procuring equipment via supply chains must mitigate the risks of offshoring servers, software or any other infrastructure used to house data and handle private customer information. The process of cyber supply chain risk management oversees every step in the procurement process to ensure that manufacturers and vendors follow cybersecurity best practices and do not violate compliance.

Cybersecurity Education and Training Begins Here

Here’s how your free trial works:

- Meet with our cybersecurity experts to assess your environment and identify your threat risk exposure

- Within 24 hours and minimal configuration, we’ll deploy our solutions for 30 days

- Experience our technology in action!

- Receive report outlining your security vulnerabilities to help you take immediate action against cybersecurity attacks

Fill out this form to request a meeting with our cybersecurity experts.

Thank you for your submission.

What Is Cyber Supply Chain Risk Management (C-SCRM)?

Cyber Supply Chain Risk Management (C-SCRM) is a comprehensive approach to managing the risks associated with third-party vendors and suppliers in an organization’s IT infrastructure. As organizations increasingly rely on external partners for various aspects of their operations, ensuring that these relationships do not introduce vulnerabilities into the company’s IT systems is crucial.

C-SCRM involves identifying, assessing, and mitigating potential cyber threats within supply chains while ensuring compliance with industry standards and regulations.

In addition to traditional product-based supply chains where physical goods are exchanged between organizations, modern businesses must also consider service-oriented supply chains. Organizations may exchange services, like cloud computing or SaaS applications, in service supply chains. These relationships can introduce potential cyber risks into an organization’s infrastructure and must be managed through effective C-SCRM practices.

The Components of C-SCRM

- Risk Identification: Recognizing potential sources of risk within your organization’s supply chain by evaluating vendor security practices, software development processes, and hardware components used in products or services supplied by vendors.

- Risk Assessment: Analyzing identified risks based on their likelihood and impact on business continuity. This includes understanding how specific cyber threats, such as data confidentiality or system availability, could affect your organization’s assets.

- Risk Mitigation: Implementing appropriate security measures to reduce exposure to identified risks. This may involve updating internal policies, enhancing technical controls like firewalls or encryption methods, or working closely with vendors to improve their own cybersecurity posture.

- Maintaining Compliance: Ensuring that all parties involved in your supply chain adhere to relevant industry standards and regulatory requirements related to cybersecurity. Examples include GDPR for data protection in Europe or NIST guidelines for federal contractors in the United States.

By implementing a robust C-SCRM strategy, businesses can better protect their information technology assets from potential cyber threats originating within their supply chain while maintaining compliance with industry standards and regulations. This proactive approach to risk management helps ensure business continuity in the face of evolving cybersecurity challenges.

Why Is C-SCRM Important?

As the reliance on third-party vendors and suppliers grows, so does the risk of cyber-attacks, necessitating effective C-SCRM strategies. C-SCRM emphasizes maintaining business continuity against these threats while ensuring compliance with industry standards and regulations and mitigating risks associated with supply chains.

Maintaining Business Continuity

In today’s interconnected world, disruptions to one part of a supply chain can have far-reaching consequences for organizations. A successful cyber breach on a provider or seller could cause substantial downtime, economic losses, harm to the company’s reputation, and even legal liabilities for the afflicted organization. By implementing effective C-SCRM practices, businesses can proactively identify potential vulnerabilities within their supply chains and take necessary steps to mitigate them before they lead to severe consequences.

Ensuring Compliance With Industry Standards and Regulations

Organizations across various industries are subject to numerous regulations that require them to maintain specific security measures when handling sensitive information. For example, companies operating within healthcare must adhere to the Health Insurance Portability Accountability Act (HIPAA), while those dealing with payment card transactions must comply with Payment Card Industry Data Security Standard (PCI DSS). Non-compliance may result in hefty fines or penalties for organizations.

By incorporating robust cyber supply chain risk management practices, organizations can ensure their vendors and suppliers meet required industry standards – reducing regulatory risks and potential legal issues.

Mitigating Risks Associated With Supply Chains

As cybercriminal tactics continue to evolve, organizations must stay one step ahead in identifying and mitigating potential threats. C-SCRM helps businesses uncover vulnerabilities within their supply chains that could be exploited by malicious actors, such as:

- Unauthorized access to sensitive data through compromised vendor systems.

- Infiltration of malware or ransomware via software updates from suppliers.

- Data breaches resulting from weak security measures implemented by third-party service providers.

- Phishing attacks targeting employees that regularly interact with vendors or suppliers.

By understanding these risks and implementing appropriate security controls, organizations can significantly reduce the likelihood of falling victim to a costly cyber-attack stemming from their supply chain partners.

Understanding Cyber Supply Chain Attacks

Cyber supply chain attacks are malicious activities that target an organization’s IT infrastructure through its vendors or suppliers. These attacks include malware, phishing, ransomware, data breaches, and other malicious activities.

These supply chain attacks aim to exploit vulnerabilities in organizations’ supply chains to gain unauthorized access to sensitive information or disrupt business operations.

The Anatomy of a Cyber Supply Chain Attack

While cyber supply chain attacks take many shapes, they typically follow a series of tactics and steps:

- Infiltration: The attacker identifies a weak link in the supply chain – usually a vendor or supplier with inadequate security measures – and accesses their systems.

- Lateral Movement: Once inside the targeted system, the attacker moves laterally within the network to compromise additional systems and gather valuable information about the organization’s IT infrastructure.

- Payload Delivery: With sufficient knowledge about the victim’s environment, attackers deploy their payload explicitly designed for that environment.

- Data Exfiltration / Disruption: Finally, attackers exfiltrate sensitive data from compromised systems or launch disruptive actions such as encrypting files for ransom demands (ransomware) or causing service outages (DDoS attacks).

Risks Associated With Cyber Supply Chain Attacks

Cyber supply chain attacks pose several risks to organizations that rely on third-party vendors and suppliers for critical IT services or products:

- Data Breaches: Sensitive information such as customer records or intellectual property may be exposed during an attack.

- Business Disruption: Operations may grind to a halt due to service outages caused by malware infections or other cyber threats.

- Financial Losses: Organizations could face costly recovery efforts following an attack, including expenses related to remediation measures, legal fees, and regulatory fines.

- Reputational Damage: A company’s reputation can suffer significantly from a high-profile cyber supply chain attack, potentially leading to lost customers and reduced revenue.

Understanding cyber supply chain attacks is a complex and ever-evolving topic that requires knowledge of current trends, attack vectors, and mitigation strategies. Organizations can proactively protect their assets from malicious actors by implementing best practices for C-SCRM outlined in the next heading.

How to Be Proactive

Companies restricted by rigorous compliance regulations and working with sensitive data must be proactive when ordering goods and services. The best way to avoid falling victim to a cybersecurity incident is to implement C-SCRM strategies, such as creating a whitelist of vendors proven to provide products and services that follow best practices in cybersecurity and compliance regulations. Regularly review the vendor list to ensure that vendors update their procedures to comply with new compliance standards.

Most organizations struggle to be compliant and review vendors. Without the right resources and knowledge, being proactive and performing the necessary supplier chain risk assessment isn’t possible. Third-party professionals can assist organizations in building a whitelist of vendors while keeping their best interests in mind.

Cybersecurity and risk best practices require proactivity, not reactivity.

Proactively assessing risk in your supply chain prevents cyber attackers from compromising critical components in manufacturing and other areas of your business that rely upon and trust a third-party vendor’s integrity.

C-SCRM Best Practices

Organizations should implement best practices for C-SCRM to effectively identify, assess, and mitigate risks associated with their supply chains. These best practices not only help in protecting against cyber threats but also ensure vendor compliance with industry standards and regulations. Here are some essential C-SCRM best practices:

- Conduct Regular Risk Assessments: Organizations must perform periodic risk assessments of their entire supply chain ecosystem. Evaluate existing security measures and the protection posture of vendors/suppliers regularly for a complete risk assessment, referencing NIST SP 800-161 guidance. The NIST Special Publication 800-161 provides guidelines on how to conduct a comprehensive risk assessment.

- Create a Vendor Security Policy: Develop a clear policy outlining your organization’s expectations regarding vendor security measures, information technology infrastructure, and business continuity plans. Ensure all vendors abide by the outlined policy before committing to contractual arrangements.

- Maintain Visibility Across Your Supply Chain: Implement tools that provide real-time visibility into your entire supply chain network, including third-party service providers and subcontractors. This lets you quickly detect potential vulnerabilities or breaches within your supply chain.

- Prioritize Supplier Segmentation Based on Risk Profile: Classify suppliers based on their level of access to sensitive data or critical systems within your organization’s IT infrastructure. Allocate resources accordingly by focusing more attention on high-risk suppliers while maintaining necessary oversight over low-risk ones.

- Incorporate Incident Response Plans for Supply Chain Attacks: Create an incident response plan specifically tailored towards addressing cyber supply chain risks. This plan should include steps to identify, contain, and remediate potential threats from your organization’s service supply chains.

- Monitor Vendor Compliance: Regularly monitor vendor compliance with industry standards and regulations such as the General Data Protection Regulation (GDPR) or the Health Insurance Portability and Accountability Act (HIPAA).

By implementing these C-SCRM best practices, organizations can effectively manage their cyber supply chain risks while maintaining a secure IT infrastructure and ensuring business continuity in the face of ever-evolving cyber threats.

The C-SCRM best practices outlined in this article provide a comprehensive overview of the steps to mitigate cyber supply chain risk. Moving forward, conducting a thorough cyber supply chain risk assessment is key for identifying potential vulnerabilities and developing strategies to reduce risks.

Performing a Risk Assessment

A supplier risk assessment performed in-house or using a third-party vendor should follow a sound strategic approach. A supply chain risk assessment determines if any process in the supply chain poses a threat to data privacy or your intellectual property. Any risk must be mitigated, or the organization could risk hefty fines for compliance violations.

Standard risk assessments often overlook the supply chain, even though the wrong vendor can cause serious cybersecurity issues. It may be tempting for organizations to lower costs by working with a cheaper offshore vendor. However, the increased risk of potential cyber threats often destroys any savings. For example, if vendors don’t implement proper security controls, installing poorly secured technology upgrades could lead to data breaches of your own systems, allowing attackers to steal data by exploiting third-party vendor systems.

Why You Need Cyber Supply Chain Risk Management

Vendors play a key role in supplying critical software and infrastructure within an organization, which is why cyber supply chain risk management is required. Manufacturers that build technology solutions use third-party vendors to make components. These components are sent to the manufacturer and are used to create the final product. Vendors must use manufacturer-specific designs and not add hardware that would leave the manufacturer’s products vulnerable to cyber attacks.

Vendors who supply such solutions require a reputation of trust, but even trusted vendors make mistakes. Risk assessments continually validate products or services to ensure cybersecurity controls are in place and components are tested for vulnerabilities.

Effective S-SCRM of your supply chain can help your organization protect its reputation. Risks associated with the supply chain can damage its reputation, impacting revenue from loss of customers and trust in the organization. Offshore attackers exploiting an organization’s vulnerabilities can damage its reputation, creating a domino effect where lawsuits pile up and threaten the company’s stability.

Consider a server that transfers financial data from the merchant to a banking institution. Attackers at the supply chain could inject tiny microchips used to eavesdrop on data. If the equipment is not reviewed, this component remains undetected. So, the server is installed within the data center infrastructure, saddling it with vulnerabilities. The component could also provide a backdoor to offshore attackers. Should this happen, it could take years before the organization notices suspicious activity.

5 Strategies to Effectively Manage Supply Chain Risk

To effectively detect and mitigate risk, you need the right S-SCRM framework and strategies that define every step in the process. Without a plan, critical mistakes could leave the organization vulnerable to cyber-attacks, leading to hefty fines for compliance violations. The following strategies can help you perform a supplier risk assessment and manage risk efficiently.

- Know Your Suppliers: The first step in supply chain risk management is knowing your suppliers. Large organizations can lose track of their vendors, leaving the supply chain open to any attacker. Every business unit that works with a supplier for infrastructure should coordinate with IT to ensure that equipment is tested and validated for compliance.

- Know Cyber-Risks of Products/Services: With suppliers inventoried, the next step in your supply chain risk management strategy is identifying risks associated with each vendor and its products. Performing a supply chain risk assessment includes assigning a specific priority to each risk and categorizing them into their particular business processes. For example, vendors for financial systems are assigned high priority due to the sensitive data stored on these systems and fall into the financial planning process category.

- Calculate Risks: Determining supply chain risk requires a professional risk analysis. The formula to analyze risk is:

Risk = Data Breach likelihood * Impact of a Data Breach / Cost

The likelihood and impact are determined by cybersecurity experts who can determine if a specific component could be breached. Once all factors in the calculation are defined, only then can you assess total risk. - Monitor Vendors for Risk: Once you’ve determined supply chain risk, continue to monitor vendors and their equipment for future vulnerabilities. Compliance rules change throughout the years, and those changes must be considered as you reassess vendor equipment and your supply chain. Changes to compliance regulations could put any vendor in violation, so continual monitoring immediately indicates when this happens.

Conducting a Cyber Supply Chain Risk Assessment

A crucial aspect of cyber supply chain risk management is conducting regular risk assessments to identify potential vulnerabilities in your organization’s supply chain. These assessments should focus on evaluating the security posture of vendors and suppliers, as well as the effectiveness of existing security controls.

1. Identify Critical Suppliers and Vendors

The first step in conducting a cyber supply chain risk assessment is identifying which suppliers and vendors are critical to your organization’s operations. This includes those that provide essential services or products, have access to sensitive data, or whose failure could significantly impact business continuity.

2. Assess Supplier Security Posture

Once you’ve identified critical suppliers and vendors, it’s important to assess their security posture by reviewing their information technology infrastructure, policies, procedures, and any relevant certifications (e.g., ISO 27001).

3. Evaluate Existing Security Controls

Evaluating the effectiveness of current security measures within your own organization is also vital when assessing cyber supply chain risks. Review all implemented controls such as firewalls, intrusion detection systems (IDS), and encryption protocols for data transmission/storage, among others, while ensuring they align with industry best practices like NIST SP 800-53 Rev 5 guidelines.

4. Identify Potential Vulnerabilities and Threats

Analyze the information gathered from supplier assessments and internal security control evaluations to identify potential vulnerabilities or threats within your supply chain. This could include outdated software, weak access controls, or insufficient vendor activity monitoring.

5. Prioritize Risks Based on Impact

Prioritizing risks based on their potential impact is essential for effective cyber supply chain risk management. Consider factors such as financial loss, reputational damage, and legal/regulatory penalties when ranking identified risks in order of importance.

6. Develop Mitigation Strategies

Construct a program to resolve prioritized dangers by incorporating additional safeguards (e.g., multi-factor authentication), upgrading current controls (e.g., revising firewall settings), or collaborating with providers/merchants to upgrade their cybersecurity techniques.

7. Monitor and Review Risk Assessment Results Regularly

Risk assessment should be an ongoing process that includes regular monitoring and review of results to ensure continuous improvement in managing cyber supply chain risks effectively.

Incorporating these steps into your organization’s C-SCRM strategy will help you proactively identify, assess, and mitigate potential vulnerabilities in your supply chains while maintaining business continuity amidst evolving cyber threats.

Protecting Data From Supply Chain Threats

After you identify your supply chain risks, you’ll find that many threats start with a malicious email targeting internal employees. The most effective defense against supply chain threats is to use email security and protection solutions to stop messages from reaching the intended recipient. You can protect data from supply chain threats triggered by an email using several strategies:

- Use Domain-based Message Authentication, Reporting and Conformance (DMARC) on your email server. DMARC will detect spoofed senders and stop them from reaching someone’s email inbox.

- Train users to detect malicious email messages. Security awareness training has been shown to reduce risk by empowering users to detect and report malicious email senders.

- Be responsive to user reports. When users know they correctly identified malicious emails, social engineering and phishing attacks, their knowledge and training are fortified.

You may not be able to control the supply chain vendor, but you can perform other actions to protect data if one of your vendors falls victim to phishing and other threats. These tips will protect you from current threats, but remember that attackers continue to craft new methods to overcome cybersecurity protections. However, the following strategies will help protect your organization from supply chain risks:

- Know your suppliers. Your suppliers have suppliers, and those suppliers have suppliers. You can better determine your risk and the cybersecurity needed to protect your environment if you know every vendor in the supply chain.

- Perform a pen-test and audit of equipment. Attackers hide much better when they include malicious circuits and components in your equipment. So, you should review any equipment connected to your environment.

- Use automation to configure equipment. Misconfigurations happen, even from vendors. Configurations should be automated to minimize mistakes.

How Proofpoint Can Help

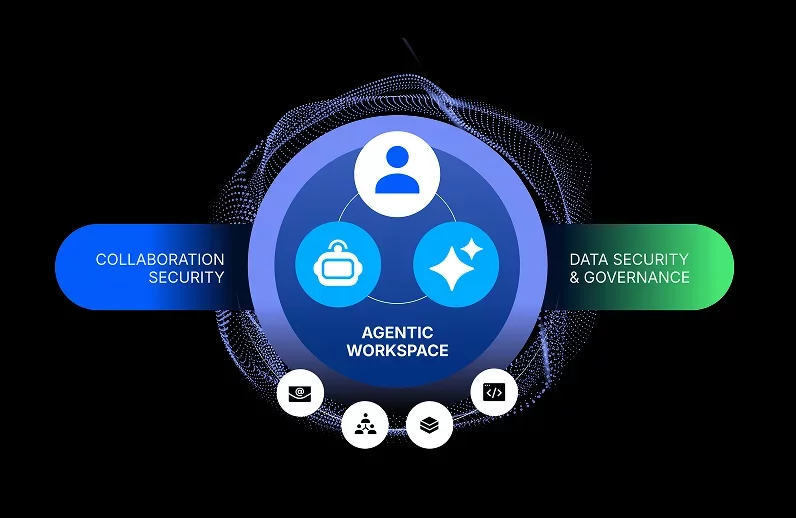

Managing cyber supply chain risks is critical to ensure business continuity and protect sensitive information. Proofpoint offers a comprehensive suite of supply chain security solutions designed to help organizations effectively manage their cyber supply chain risk. These solutions include:

- Threat Intelligence Services: Stay ahead of potential threats by leveraging actionable intelligence on emerging vulnerabilities, threat actors, and attack methodologies targeting your organization’s supply chains.

- Threat Response Capabilities: Respond quickly to incidents involving your supply chain partners with coordinated response efforts that minimize downtime and reduce the impact on operations.

- Email Security Solutions: Protect against phishing attacks targeting employees or suppliers by implementing robust email security measures such as advanced filtering techniques, real-time threat analysis, and user awareness training programs.

- Enterprise Data Loss Prevention: Mitigate the risk of data breaches caused by compromised vendor systems or unauthorized access through effective DLP strategies that monitor for sensitive information transmitted outside the organization without proper authorization.

In addition to these powerful solutions, Proofpoint also provides expert guidance on best practices for managing cyber supply chain risks. By partnering with Proofpoint, organizations can gain valuable insights into industry standards and regulations relevant to their specific sector while benefiting from tailored recommendations based on unique business needs.